Crosslink Powder Coating of Texas, LLC is proud to be the powder-coating of choice for industry leaders in Fort Worth and surrounding areas.

Powder coating provides maximum protection at a price point that creates value for all in the supply chain. Powder coating is environmentally friendly, and the quality of the finish is durable and attractive.

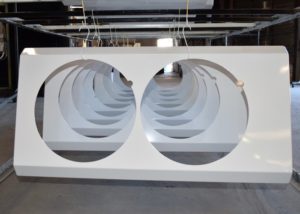

Our powder coating facility features a 54-foot oven (the biggest in North Texas) to handle your large pieces. We also have a 96-inch Wheelabrator to prep or finish metal and concrete pieces, plus sandblasting services to restore, prep, or finish various pieces up to 54 feet long. We take pride in offering the highest quality coatings and rapid turnaround times.

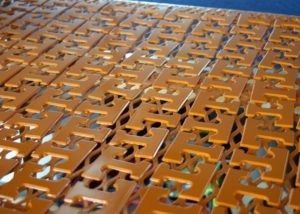

Metal fabricators appreciate our rapid turnaround and superior customer service. We even offer tracking capability for our clients to check on the progress of their Wheelabrator shot blasting job or the stage of their powder coating project. We’re known for our responsiveness: when you call, a human being will answer or return your call promptly. All our clients value our pick-up and delivery services, making it easy for them to send parts out for coatings and receive them, looking fresh and new, without having to own or rent their own truck transportation.

At Crosslink Fort Worth, we know how critical finishing is to the durability of the parts you produce and the equipment you use. Wheelabrator blasting can restore rusty parts or prep the surfaces of new parts and components for the application of paint or coatings.

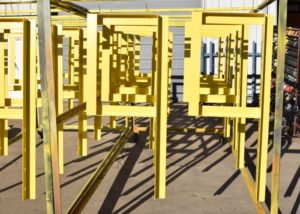

One of the major benefits of our powder coating facility is the variety of colors powder coating can offer. With your choice of several hues, you can color-code movable equipment or railings for separate sectors of your facility. Use colors of powder coating to indicate where equipment belongs in your large plant or warehouse or to indicate the team-member grade that is qualified to use it. Bright colors like white or yellow can increase visibility for safety, while red color may alert workers that equipment or sectors in your plant can be hazardous.

Powder coating is versatile. Because powder coatings are sprayed on, they can reach every surface of a complex railing system, fence, machine, or pipe system that can fit in our enormous oven for curing.

Better still, powder coating is environmentally friendly. The pigment powders are free from hazardous volatile organic compounds. They adhere to metal through an electrostatic process: the charged surface attracts the powder, which adheres to the surface and bonds through the heat curing process, minimizing waste. Excess powder, if any, can be retrieved and reused. Our powder coating facility has the proper ventilation and cleaning systems to ensure your job is performed perfectly, with results that exceed your expectations.

Powder coated surfaces are easy to clean and maintain. With proper care, powder coated items should retain their like-new appearance for years to come.

In addition to powder coating and Wheelabrator shot blasting, we provide ceramic coating services. Truck and auto parts fabricators have become familiar with the rising popularity of ceramic coatings. Crosslink Fort Worth provides ceramic coating services. Ceramic coatings cure at 750° and resist chipping and pitting while insulating against radiant heat. These coatings are useful for any parts that must endure high heat or are exposed to rough conditions like blowing sand or gravel roads.